Yageo and Jabil: Navigating Rapid Market Growth

Jabil Supply Chain Profiles in Excellence

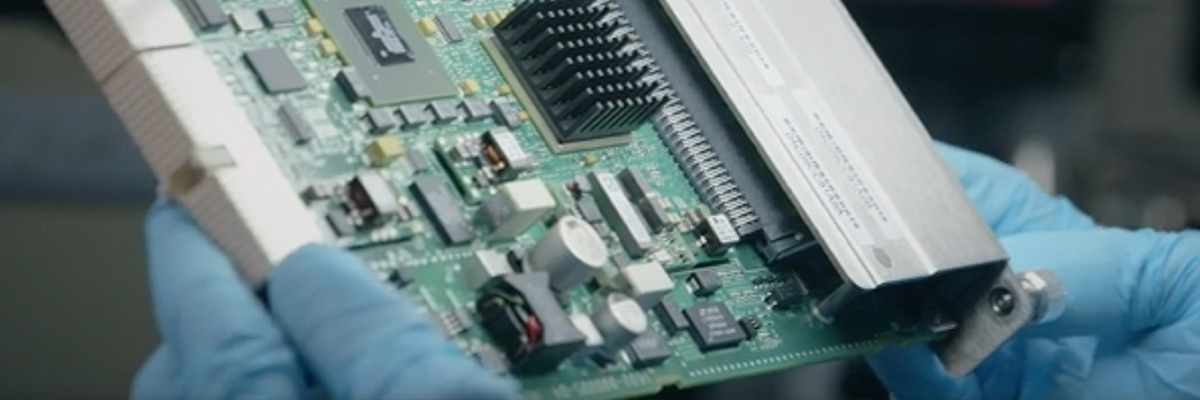

YAGEO: Supplier case study

Yageo Corp. is a leading maker and supplier of passive electronic components with a global reach that includes 19 manufacturing sites, five R&D centers as well as production and sales presence in Asia, Europe and the Americas. Founded in 1977 and headquartered in Taipei, Yageo provides customers with one-stop shopping for an extensive product portfolio of resistors and capacitors as well as wireless and circuit protection components.

Yageo has been one of Jabil’s primary passive component suppliers for more than a quarter century. “Yageo has a long history of supporting Jabil’s various lines of business,” says Adam Ng, Director of Supplier Relationship Management at Jabil. “During my 10 years with the company, I have witnessed this relationship continue to grow as both parties strive together to meet the challenges and changes of an evolving business climate.”

The partnership between Jabil and Yageo has been fortified over the past decade, with Jabil providing engineering services to its global customers. “Jabil is quite unique because it’s not just like a customer to us,” explains Roger Cheng, Sales Director at Yageo. “Jabil is one of our key partners in the global EMS segment. I think it is the greatest EMS company we work with.”

“Jabil is one of our key partners in the global EMS segment. I think it is the greatest EMS company we work with.”

- Roger Cheng, Sales Director, Yageo

Open Lines of Communication

To keep the exemplary balance of this partner-supplier relationship requires open lines of communication. Jabil and Yageo hold bi-annual strategic meetings, perform detailed quarterly business reviews and collaborate on technology roadmaps. “There’s an ease of doing business together as we’ve grown as partners in meeting business challenges and market demands,” notes Ng. “Yageo’s team has proven to be flexible and open minded in accommodating sudden market changes and disruptions.”

In particular, Yageo responded with speed and agility addressing market fluctuations caused by COVID-19. Regular meetings with Jabil’s Global Commodity Management and Supplier Relationship Management teams ensured weekly interactions and up-to-the-minute exchanges of market, customer and technology updates. “Our relationships extend to the executive level, which helps align everyone around common goals,” adds Ng. “Together we review opportunities and strategize how best to meet increased demand.”

When the pandemic exposed shortcomings in supply chains and ignited sudden business disruptions, Jabil and Yageo leaned on their years of experience dealing with constrained component supplies. “It’s been critical to maintain constant communications to understand available capacities,” says Ng. “We have aligned our technology roadmap and brought design and engineering teams together to understand the impact of restricted supply resources as well as trends driving pent-up demand, such as what is happening in 5G and automotive.”

Maximizing Partnership Value

One of the most effective partnership strategies Jabil has put in place are Supplier Value Maps that not only examine a supplier’s market and technology alignments but focuses on financial health. The result is a comprehensive strategy that guides the relationship. “The key is understanding the technology roadmap and navigating it together,” says Ng. “Then the sweet spots will emerge quicker and this will drive innovation while also improving time to market.”

As a result, Yageo and Jabil identified and prioritized strong growth opportunities where both companies can focus on design and technology R&D efforts. “Jabil has a lot of business in terms of the 5G automotive and the medical market,” says Cheng. “We also are focusing on those advanced technologies, so we can work together to penetrate more and more AVL BOM in existing and new 5G and automotive customers.”

Real-Time Supply Chain Visibility

Jabil’s digital supply chain and procurement intelligence platforms offer unique, real-time visibility to deliver meaningful insights and improve decision making. This centralized approach takes partner engagement to the next level.

“Jabil came to us early and with a sense of urgency during a supply shortage,” recalls Cheng. “We guaranteed our supply, our pricing and our commitment to our customers. The partnership is even stronger during the hard times.”

Yageo also benefits from access to Jabil’s supply chain intelligence and centralized procurement to confirm logistics and delivery status on a daily basis. “From this system, we don't have to deal with procurement sites all over the world,” explains Cheng. “We can save our time and our resources on more meaningful things, so that brings us a lot of convenience. We have very awesome interactions with the team at Jabil.”

The heartbeat of this digitized approach is having accurate and up-to-date supply chain information. “Constantly feeding in good data produces good analytics,” says Ng. “Jabil provides Yageo with accurate forecasts and that helps them help us. That’s what a good relationship is all about.”

| Company | Yageo Corporation |

| Industry | Electronic manufacturing company |

| Country | Worldwide |

| Employees | 5,000+ |

| Website | yageo.com |

How can we help you?

Contact us.

Related Case Studies

Related Blog Posts

Jabi's Supply Chain Capabilities

Learn More About Jabi's Supply Chain Capabilities