From 3D printing tools and fixtures to using augmented reality to guide a repair job to adopting robots that take on strenuous tasks for human workers, the manufacturing industry is going as high-tech as an industry can get.

These innovations, in tandem with the industrial internet of things (IIoT), cloud applications and infrastructure, big data analytics and more, are changing the way business is conducted. Some innovations make work easier or more efficient, and others offer more data feedback to assist with substantial enhancements.

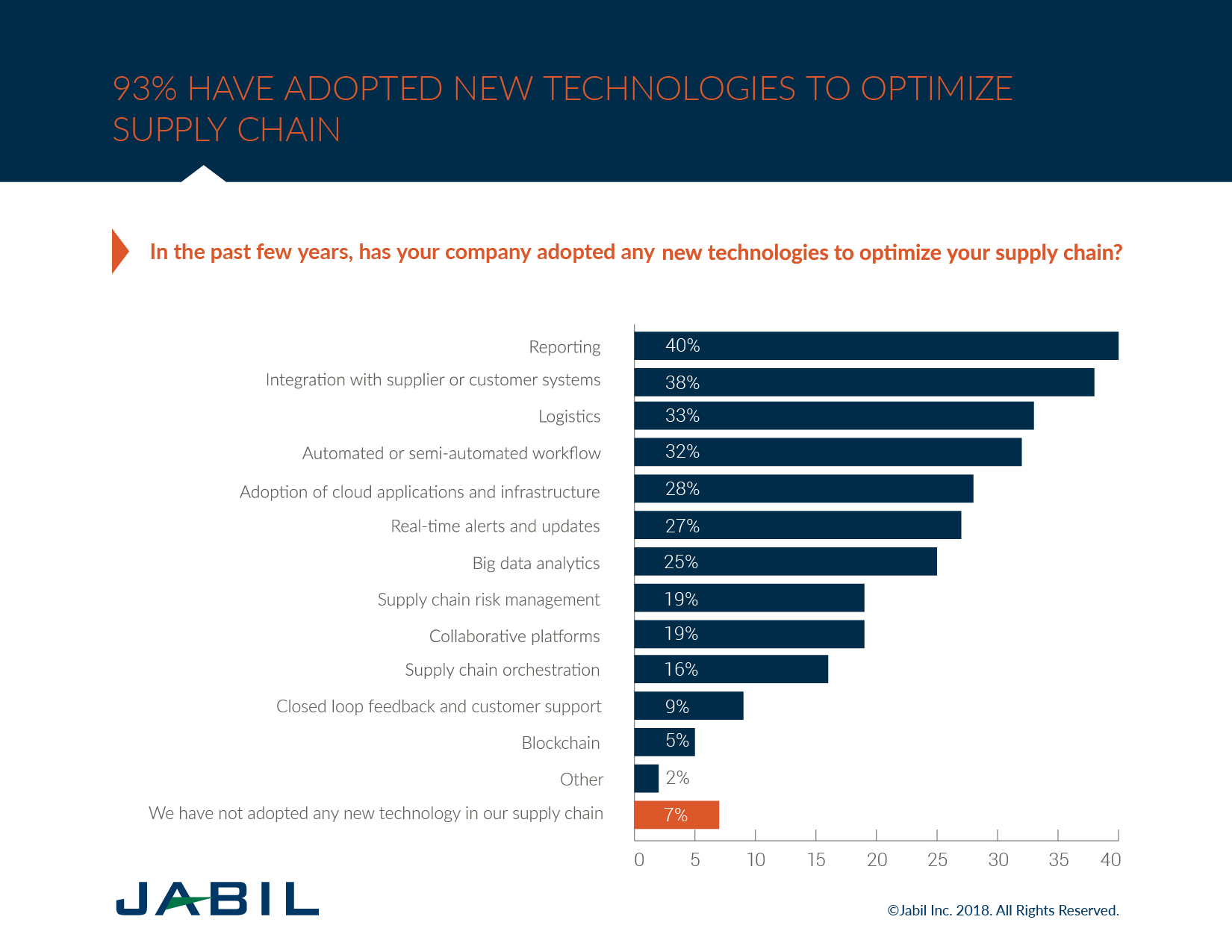

In the past few years, 93 percent of surveyed companies have adopted new technology that impacts their business in some way, according to Jabil’s 2018 Supply Chain Technology Trends report. Slowly but surely, these companies are saving funds to purchase and implement new technology. According to the survey, 85 percent of respondents have a dedicated or a placeholder budget for supply chain technology improvements in the next two years.

Most investments so far have been in the more mundane types of supply chain technologies. For example, 40 percent of the more than 300 manufacturing professionals surveyed indicated that their companies invested in reporting technologies, 38 percent said their companies have focused on integration with supplier or customer systems, 33 percent noted that their employers have spent money on logistics solutions, 32 percent acknowledged that their companies have moved toward an automated or semi-automated workflow and 28 percent reported that their companies have adopted cloud solutions.

Investments in Supply Chain Risk Management Tools

Only about half of the respondents to the survey have invested in any sort of real-time dashboard with monitoring and alerts. But for any supply chain, it is important to have visibility and alerts to minimize disruptions. Even more alarming is that less than 20 percent of respondents have any type of attribute-based risk profiles or prescriptive analytics to support a proactive supply chain environment. These are essential in today’s highly volatile and dynamic environment.

Research and advisory company Gartner lists prescriptive analytics as one of the top eight supply chain technology trends for 2018. “Prescriptive analytics can improve decision-making in functional areas like supply chain planning, sourcing, and logistics and transportation and can be deployed to improve end-to-end supply chain performance,” Christy Pettey writes on the Smarter with Gartner blog. She adds that prescriptive analytics also can empower processes that previously relied solely on human judgment, which could, in turn, create more efficiencies and allow humans to focus on more valuable tasks and projects.

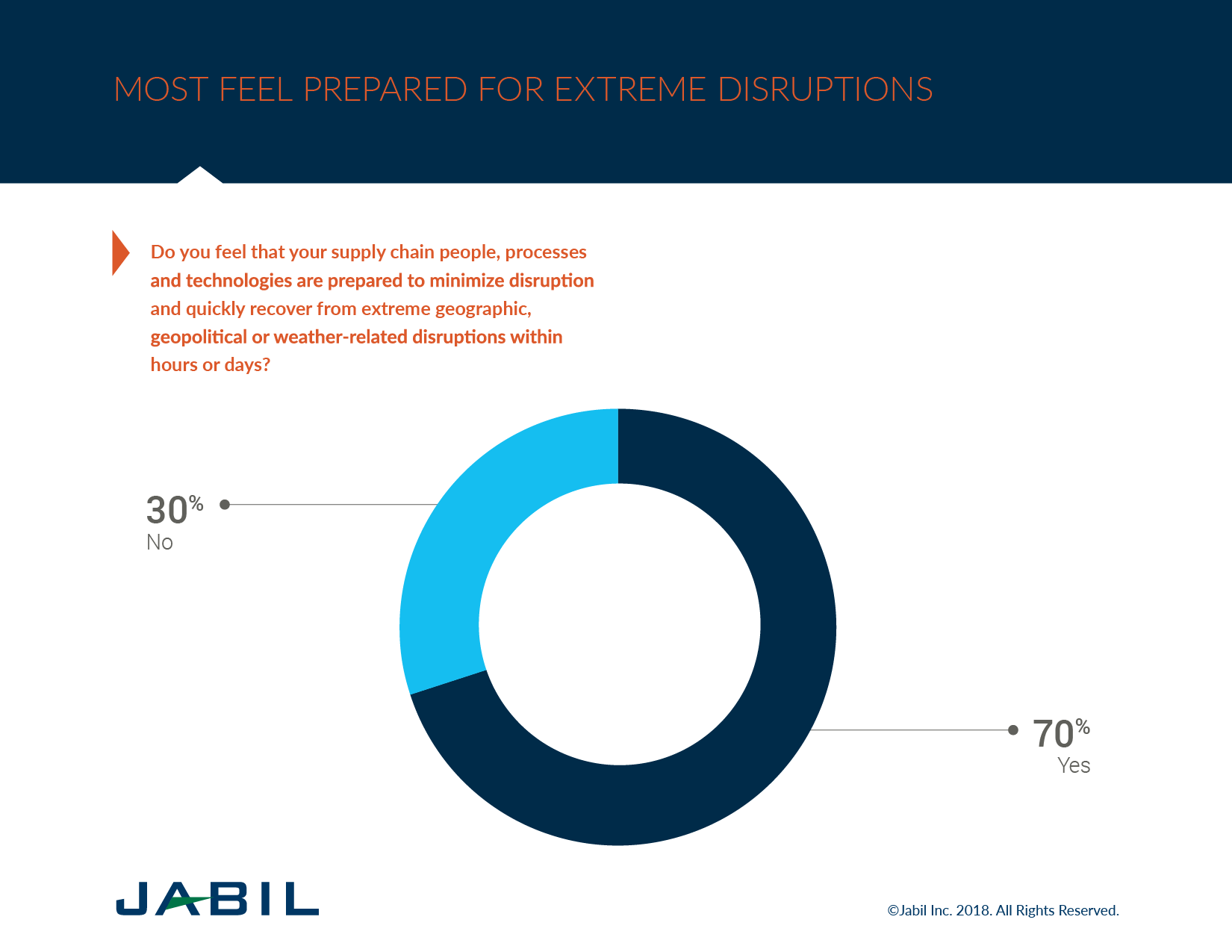

There also are supply chain technologies available for handling the aftermath of disasters, such as recovery and collaboration technology and big data analytics with real-time visibility. These supply chain technologies are important because they can help companies improve recovery times and decrease disruptions following a disaster or other interruption. However, only 31 percent of respondents have invested in at least one of these technologies in the past two years, and only 36 percent plan to invest in at least one of these technologies in the future.

Instead, companies are investing in organizational approaches to risk management, such as training personnel, increasing efforts to identify options in the event of a disaster, prioritizing supplier collaboration and communication in case of disaster and improving internal and external communications, among other approaches. Of the surveyed companies, 70 percent said that they are prepared to recover from an extreme geographic, geopolitical or weather-related disruption within hours or days.

Emerging Technologies of the Modern Supply Chain

Only a small percentage of companies have invested in some of the newest supply chain technologies, such as collaborative platforms, proactive supply chain risk management solutions and real-time global supply chain orchestration. These technologies each have less than 20 percent adoption rate among companies surveyed. However, in the very near future, these technologies likely will be drivers of digital innovation and productivity in the supply chain. Early adopters will glean the most benefits, as they will be operating ahead of approximately 80 percent of their peers, according to the survey.

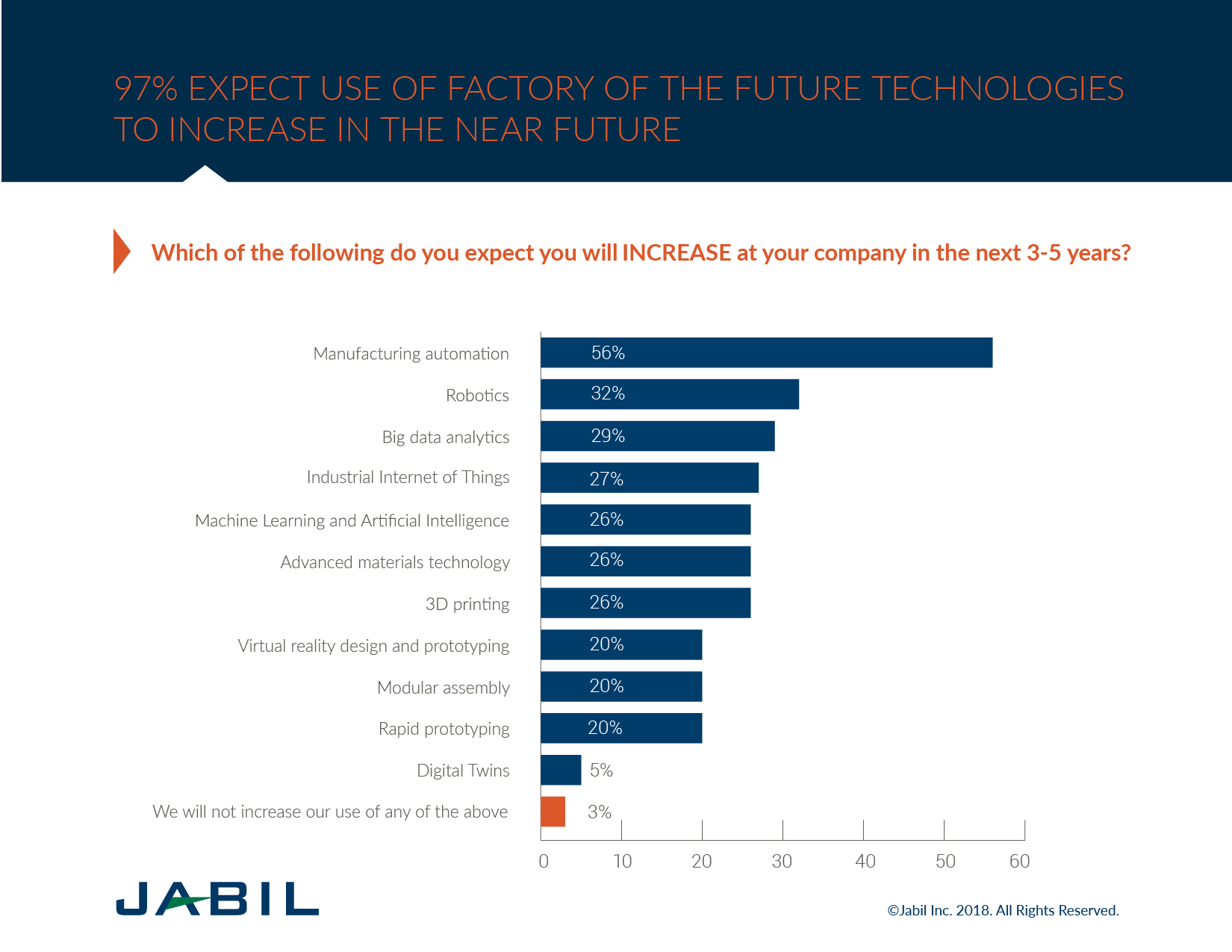

Despite their relatively low adoption rates right now, the following were identified by survey respondents as the top five technologies of investment:

- Manufacturing automation

- Robotics

- Big data analytics

- Industrial IoT

- Machine learning and artificial intelligence

AI has a strong potential to revolutionize supply chain processes, which also made Gartner’s list of the top eight supply chain technology trends of 2018. Initially, the use cases for intelligent objects, such as automated guided vehicles, are related to the objects working in defined and controlled environments, such as warehouses, in which they will assist with picking and moving products. However, AI’s capabilities to automate decision-making, alter business models and ecosystems, and reshape the customer experience could expand its use cases and even make other emerging technologies redundant.

What Will Drive the Factory of the Future?

Peering farther into the future, respondents to the Jabil survey also identified supply chain technologies that will be important to the factory of the future. The top three are increased manufacturing automation, robotics and 3D printing.

McKinsey & Company ranks manufacturing second among industry sectors in terms of automation potential. A study by the global management consulting firm found that 64 percent of the 749 billion working hours spent on manufacturing-related activities around the globe were automatable with currently available technology. If automation were implemented to handle the activities that accounted for this amount of working time, 236 million full-time employees could be repurposed.

Robotics and 3D printing already are being embraced by manufacturers. GE Aviation acquired a U.K.-based company for its technology to assist with jet engine maintenance. The company's snake-like robots can fit into tight spaces, which has previously enabled them to assist with inspecting a boring shield that was being used to install a road tunnel 164 feet below sea level, measure the sharpness of the cutting surface and clean it with a high-pressure water jet.

Volkswagen has partnered with robotics startup Wandelbots to develop a new way to train industrial robots. The robot watches a human wearing a jacket with sensors and actuators complete a task, and then the robot mimics the human’s actions to do the task itself. Another carmaker, Mercedes-Benz, utilizes 3D printing to manufacture metal spare parts as well as plastic custom and spare parts for its Mercedes-Benz trucks and Daimler buses.

Subscribe to the Jabil Blog

Sign up for weekly updates on the latest trends, research and insight in tech, IoT and the supply chain.

During our own experiments with additive manufacturing working with HP, we discovered that they could 3D print a part for a 3D printer for less than a third of the cost using traditional manufacturing methods. In addition, the 3D-printed part is 70 percent lighter. 3D printing also gave HP added design flexibility, as components that previously contained multiple sub-parts with different screws and assembly requirements instead could be produced as a single part. These use cases offer a glimpse into the construction and production worlds of the future.

What is the ROI for Supply Chain Technologies?

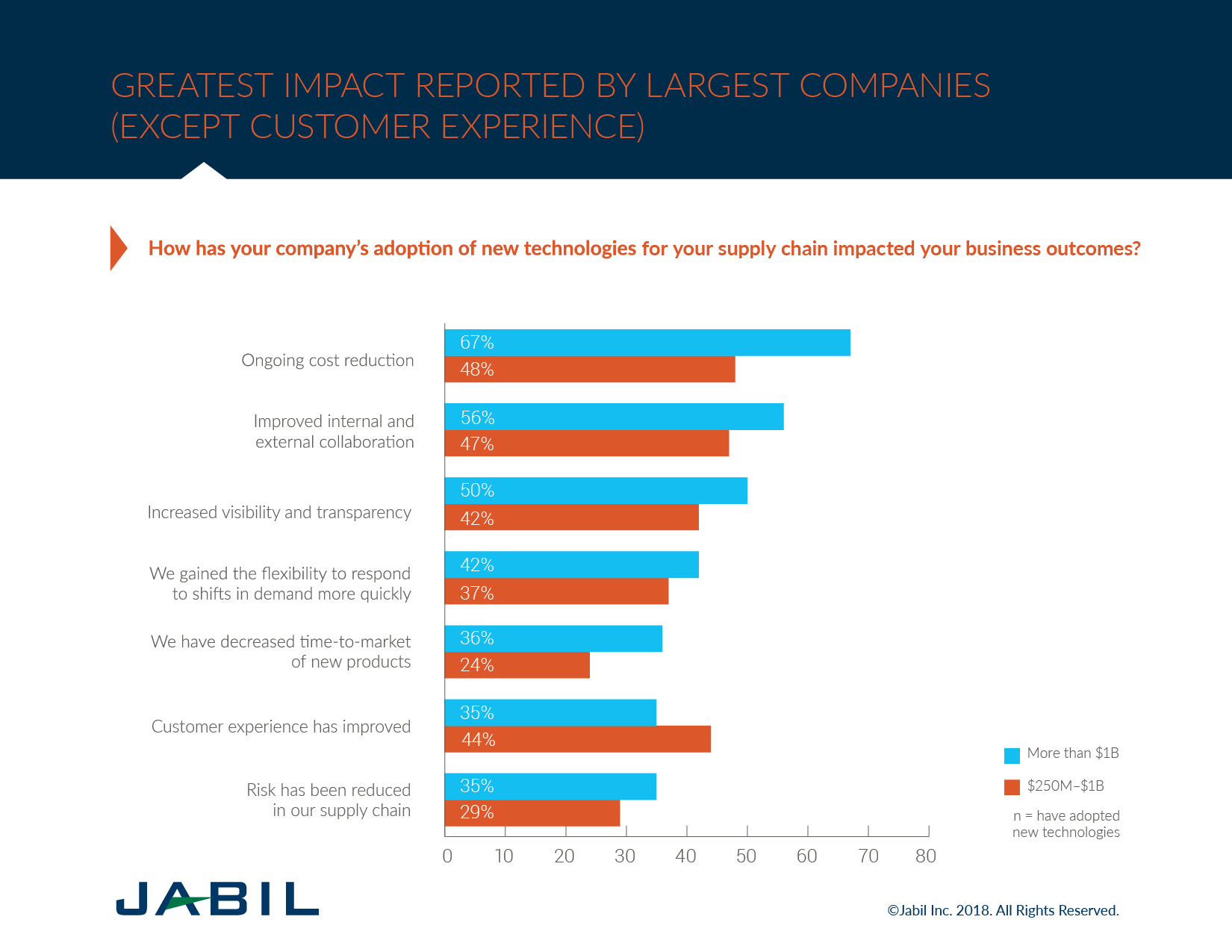

As with any type of investment, companies are concerned that adopting supply chain technologies may not be worth the risk. However, 100 percent of respondents to the Jabil survey report that they’ve already reaped benefits from their supply chain technology investments:

- 57 percent of the respondents said their companies are enjoying ongoing cost reductions.

- 51 percent noted that their companies’ technology investments improved their internal and external collaboration.

- 46 percent experienced increased visibility and transparency.

- 40 percent said they were able to respond to changes in demand more quickly.

- 40 percent recognized improved customer experiences.

- 32 percent reduced supply chain risks.

- 30 percent have been able to decrease time-to-market.

When it comes to company size, larger companies, or those with more than $1 billion in annual revenue, have gleaned larger returns on investments than smaller companies. These can be attributed to economies of scale as well as the securities of more established infrastructures and processes at larger companies. However, this should not stop smaller companies from investing, because they can and are experiencing the benefits of these technologies too.

For example, nearly half of companies with less than $1 billion in revenue experienced ongoing cost savings. In addition, smaller companies were more likely than large companies to report an improved customer experience because of their supply chain technology investments. The caveat is that smaller companies will need to conduct deeper evaluations of supply chain technologies to determine which will have the greatest impact on their operations and offer the largest return on investment given their business structures.

The bottom line is that the rate of technological advancement is accelerating, and survival, regardless of company size, will depend on keeping up with and connecting to the developing supply chain ecosystem. It is important for companies to carefully evaluate potential supply chain technology options and allocate funds to help their businesses evolve with the changing times.

Supply Chain Technology Trends

How are global enterprises investing in and adopting supply chain technologies? Learn more in this report.