Axis Communications

Innovating Surveillance Breakthroughs for a Smarter and Safer World

Axis Communications & Jabil

As the future of smart cities comes into focus, it’s clear that what’s needed most are intelligent digital solutions capable of “talking” to each other while “seeing” everything. As a result, most smart-city initiatives are seeking better ways to connect critical data points in the hopes of improving the delivery of citywide services while making all cities safer and more secure for everyone.

Global safety and security initiatives are driving ever-increasing deployments of sophisticated network video surveillance and analytics, access control and audio systems. According to MarketsandMarkets’ latest report on the global video surveillance market, greater government and stakeholder funding also is helping fuel rapid market growth, which is projected to reach $74.6B by 2025.

Since developing the very first network video camera in 1996, Axis Communications has been at the forefront of major breakthroughs across the video surveillance market. “Innovation has been in our DNA since Axis was founded,” explains Per Ädelroth, Vice President of Operations at Axis Communications. “We’re very good at uncovering customer problems and then finding innovative, smart ways to solve them to create a safer world.”

“Axis is a company known for quality—we have a great quality reputation in the market. We depend on Jabil to actually sustain that and make it come true as we manufacture higher and higher volumes.”

- Per Ädelroth, Vice President of Operations at Axis Communications

Innovations in Intelligent Security

In fulfilling its vision, Axis also brought to market the world’s first HDTV-compliant cameras and video encoders, along with a steady stream of game-changing capabilities. On average, the company launches around 50-80 new products each year, encompassing security cameras, physical access control products and radars, as well as software and recording systems.

Continuous technology advancements provide Axis Communications’ distributors, systems integrators and resellers across 179 countries with hundreds of world-class products for security, safety and operational efficiency. Over the past year, in particular, demand for the company’s low or no-contact access control systems grew as a result of COVID-19-related hygiene and social distancing concerns.

“Solving complex problems requires interdisciplinary teamwork,” adds Ädelroth. “It’s not just electronics, optics or software, but the combination of these things that leads to great, new innovative products. Our strong culture of collaboration crosses borders to address really sensitive, mission-critical security and safety applications.” Teaming with manufacturing partners has been another major part of Axis Communications’ pioneering approach to the market. To that end, the company seeks manufacturers with proven track records of accelerated growth backed by uncompromising commitments to quality and innovation. In 2013, Axis realized the addition of another global manufacturing solutions provider would best position the company to address aggressive sales growth worldwide.

In particular, Axis wanted to ramp high-volume manufacturing in the European Union, which led the team to Jabil. With more than 140,000 employees across 100 locations, Jabil offered Axis an attractive, lower-cost manufacturing location to support its entire product lifecycle from a 700,000 square foot facility in Kwidzyn, Poland. Jabil came on board in 2014; manufacturing in Poland commenced in 2015. The proximity of Jabil’s facility to Axis Communications’ headquarters in Sweden offered an advantage, as did Jabil’s Workcell business model.

The cornerstone of Jabil’s customer-centric focus, the Workcell Model features dedicated experts who work as a cross-functional team to support each customer. Jabil also demonstrated manufacturing agility, aided by world-class supply chain capabilities and industry-leading automation. Overall, Jabil was uniquely positioned to keep pace with rapid market expansion while meeting Axis Communications’ prototyping and high-volume manufacturing demands. “Axis is a company known for quality—we have a great quality reputation in the market,” says Ädelroth. “We depend on Jabil to actually sustain that and make it come true as we manufacture higher and higher volumes.”

Meeting Dynamic Market Demands

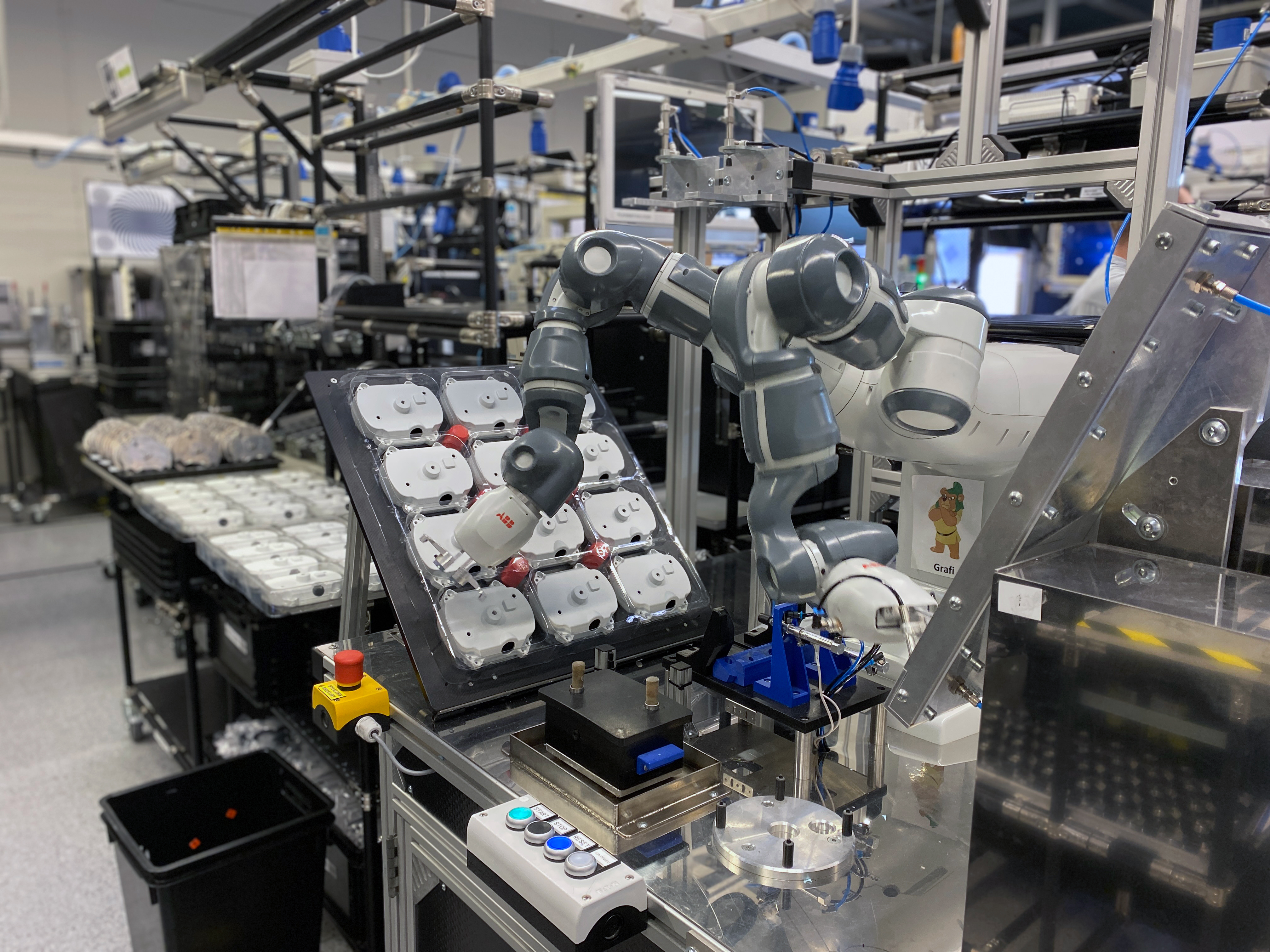

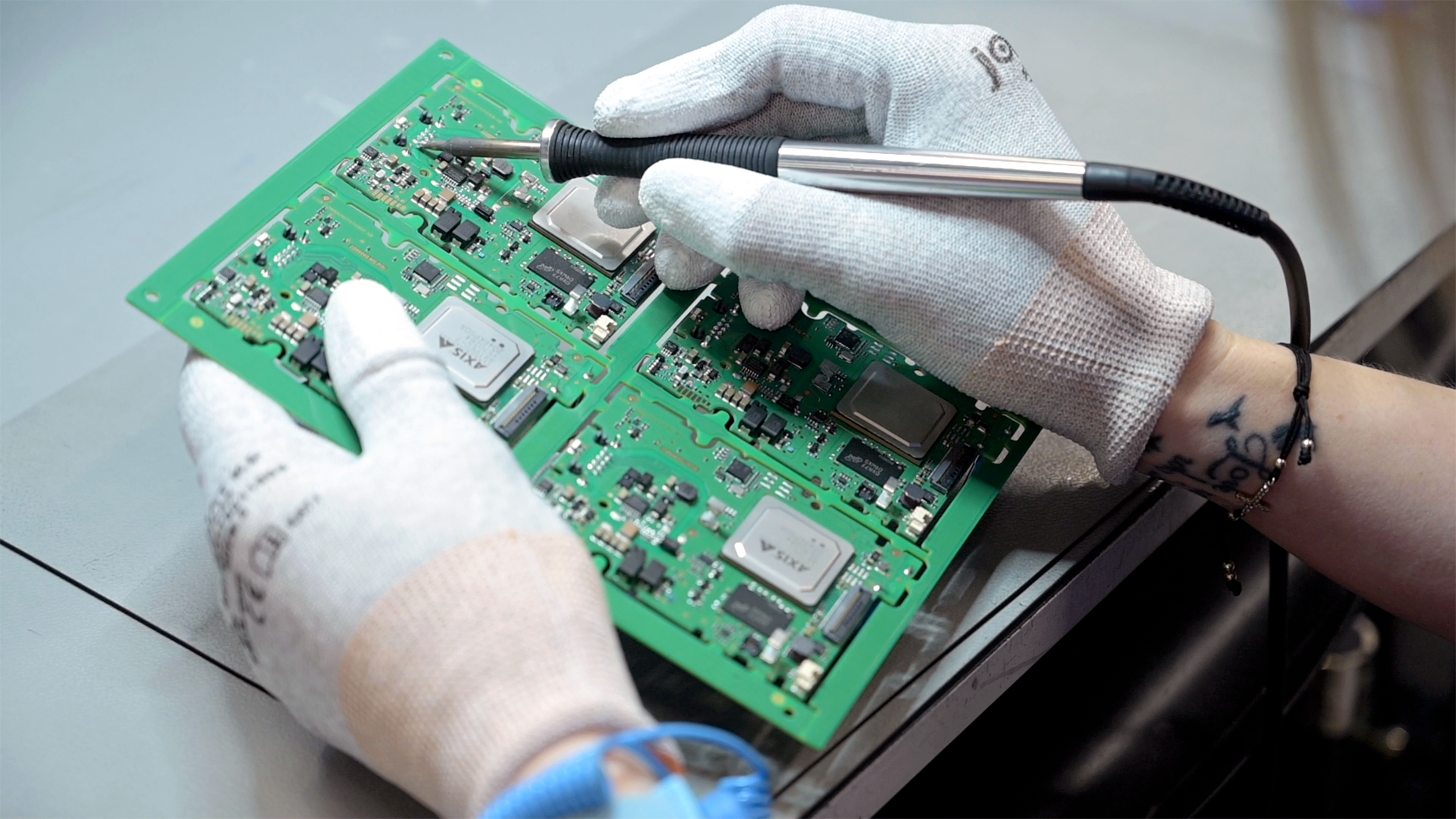

To address manufacturing capacity demands, Jabil applies in-line robotics and automation solutions that drive high-volume precision manufacturing while reducing costs. In some cases, Jabil employees work alongside robots to expedite various operations. Using equipment from Axis Communications for test and calibration, Jabil has also leveraged its cleanroom experience to build optical modules that meet stringent specifications and performance requirements.

Design for manufacturing plays an important role in introducing new products to the market. “New product introduction is really important in terms of timing and speed,” says Ulrika Magnusson, Global Supply Chain Director at Axis Communications. “We get good feedback from Jabil when it comes to how we can develop our products in a better way to ensure we can achieve fast time-to-market.”

During times of extreme market volatility, Jabil’s global supply chain team has deployed alternative sourcing strategies and recommended specific design modifications to avoid lengthy component lead times. “In 2018, the market faced major constraints,” recalls Scott Gebicke, President, Industrial Division at Jabil. “We built an excellent supply chain team that continues to mitigate risk while ensuring we have sufficient supply of the components needed for Axis Communications to grow by 15% year-over-year.”

Jabil also deployed a novel Cleanroom approach, including a “clean area” of dedicated workbenches in an ISO7 environment. The result is greater flexibility, expedited time-to-market and reduced product costs. Process innovation and total supply chain orchestration streamline everything from prototyping and procurement to final assembly, testing and packing services. Component traceability is part of a new Axis Communications’ initiative, which Jabil was brought into support from a project design and deployment perspective.

“We really trust that Jabil is focused on sourcing materials while working closely with our suppliers to ensure we have the right components in place when we need them,” says Magnusson. “Since we are producing a complex product, it’s very important to have the whole supply chain backup with all of our suppliers."

“New product introduction is really important in terms of timing and speed. We get good feedback from Jabil when it comes to how we can develop our products in a better way to ensure we can achieve fast time-to-market.”

- Ulrika Magnusson, Global Supply Chain Director at Axis Communications.

Trust and Confidence Propel Partnership

As a testament to the strong partnership with Axis Communications, Jabil can assure delivery of top-quality products to customers anywhere in the world, even as product volumes escalate. In one particular case, a huge demand surge from one of the company’s biggest customers necessitated tripling production volume within two months. Jabil not only increased technical and manufacturing capacity quickly, but the supply chain team secured additional components in a short timeframe to ensure success. “Collaboration is a true, long-term partnership where we learn from each other and listen to feedback for each other,” Magnusson adds.

A prime example of this cooperative partnership is remote assistance control using Augmented Reality/Virtual Reality (AR/VR) to keep projects on pace during the COVID-19 pandemic. When travel restrictions threatened to disrupt New Product Introductions (NPIs), AR/VR was used to unite Axis Communications’ teams in Sweden with their Jabil counterparts in Poland. Additionally, Axis leverages complete logistics services from Jabil’s Memphis, Tennessee based facility to ensure rapid, cost-effective delivery to its distribution partners.

“We do not see each other as customer and supplier, but really as partners,” explains Aleksandra Obiedzinska, Business Unit Director at Jabil.

As part of this partnership approach, Jabil has installed Axis cameras at its facilities around the world, including the new headquarters in Florida as well as other manufacturing sites. “We are building products that we use every day, which our employees rely on for safety and security,” says Gebicke. “The relationship between Jabil and Axis is strong and deep. We can talk openly and directly at all levels of the organization.”

On the Road to a Circular Economy

Another critical partnering opportunity is aligned with Axis Communications’ continual focus on reducing its carbon footprint. “Sustainability is important to both Axis and Jabil,” says Obiedzinska. “We are working together to minimize energy consumption, reduce landfill waste and increase recycling. Additionally, we are looking for ways to reduce our carbon footprint through the use of more sustainable materials and packaging.”

To that end, Jabil and Axis Communications redesigned carton packaging using sustainable materials that could be sourced locally. Both organizations are highly committed to take further steps in reducing the use of plastics and PVC in Axis’ products and product packaging while increasing the level of recyclable materials whenever possible.

“Jabil and Axis are on a great sustainability journey together,” says Magnusson. “We have good KPIs to measure our progress and are committed to driving this area together.” Jabil is aligning Axis Communications with other customers advancing green technologies, encompassing solar panels, energy storage and building automation.

Looking ahead, the organizations are well positioned to drive increased sustainability while supporting Axis Communications’ growth in the Americas, Europe, Asia and other parts of the world. “To build something that’s really strong for the total business, a manufacturing partner needs to go a little bit outside their comfort zone and that’s what we are talking about here,” concludes Ädelroth. “We push each other in good ways to build something that’s stronger, and I see that working really well with Jabil.”

| Company | Axis Communications |

| Industry | Smart Building/Security |

| Country | Sweden |

| Employees | 3,500+ |

| Website | Axis.com |

CHALLENGES

- Increased market demand for cutting-edge, complex surveillance products drove need for world-class manufacturing in the European Union

- Market volatility necessitated greater supply chain intelligence and real-time procurement insights

- Growing desire to reduce carbon footprint escalated need for improved product sustainability

SOLUTION

- Jabil supports entire production lifecycle needs at highly automated manufacturing, assembly and logistical facilities in Poland and in the U.S.

- Jabil’s global supply chain and procurement teams alleviate market constraints with new sourcing alternatives and component redesign recommendations

- Sustainability collaboration focused on reducing plastics in products and packaging

BENEFITS

- Complete support for around 40 new product introductions (NPIs) each year

- Global supply chain intelligence plays pivotal role in addressing dynamic market while enabling Axis to triple production for a key customer in two months

- Packaging redesign using sustainable materials demonstrates early commitment to sustainability, with other projects planned to reduce carbon footprint

How can we help you?

Contact us.

Related Blog Posts