Four Smart Strategies to Sustainable Packaging Design

When Thomas Edison counseled, "We should remember that good fortune often happens when opportunity meets with preparation," the inventor probably wasn't thinking about how to eliminate or reduce the quantity of plastics floating in the ocean or lying in landfills. But that doesn't mean "the Wizard of Menlo Park's" words aren't applicable to sustainable packaging design. Producing the circular economy and the ecological and economic benefits it brings requires preparation. In other words, it starts with sustainable packaging design.

Since the 1950s, annual production of plastics increased nearly 200-fold to 381 million tons in 2015, a mass equivalent to two-thirds of the world population. Worse, most of that has never been recycled; about 80 percent of all plastic generated has accumulated in landfills or the environment. Plus, with plastic production expected to rise 40 percent over the next decade, we all need to be taking action toward sustainability.

It’s a daunting task; there are multiple obstacles to achieving a truly circular economy, from weaknesses within the recycling infrastructure to a lack of consumer responsibility. Eradicating this problem will require time and effort from organizations and individuals across the world, but brands can start making an impact by focusing on designing sustainable packaging.

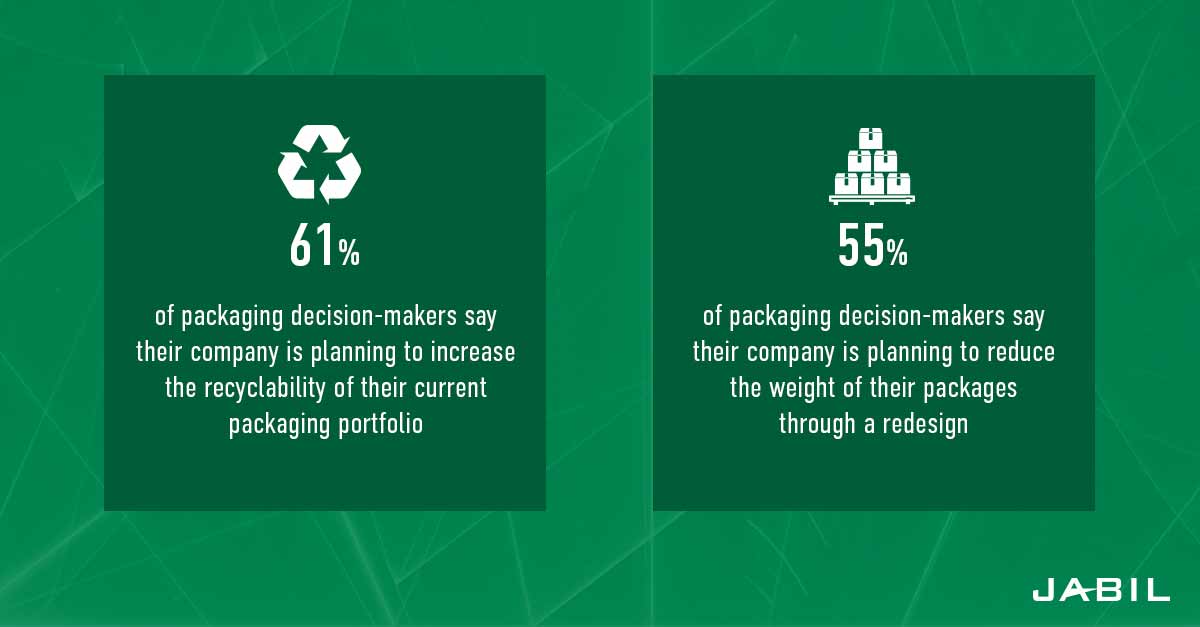

According to a recent survey Jabil conducted more than 200 packaging decision-makers, rethinking their current packaging portfolio and altering their offerings to be more sustainable is already a top priority for companies, and most designers and engineers are up for the challenge and excited to tackle innovative solutions. Download the full survey report.

To achieve the circular economy, improvements need to be made all along the “reduce, recycle, reuse, rethink” process, but creating an efficient and eco-friendly end-of-life starts from the very beginning, with sustainability-focused design.

Challenges in Finding a Comparable Plastic Alternative

Finding a material to replace plastic is more complicated than it may seem. For one thing, plastic is one of the most effective safeguards against another widespread problem: food waste. Food – either because it has spoiled, reached its expiration date or is of questionable quality – is the single largest material deposited in landfills, where it contributes heavily to the emission of greenhouse gases.

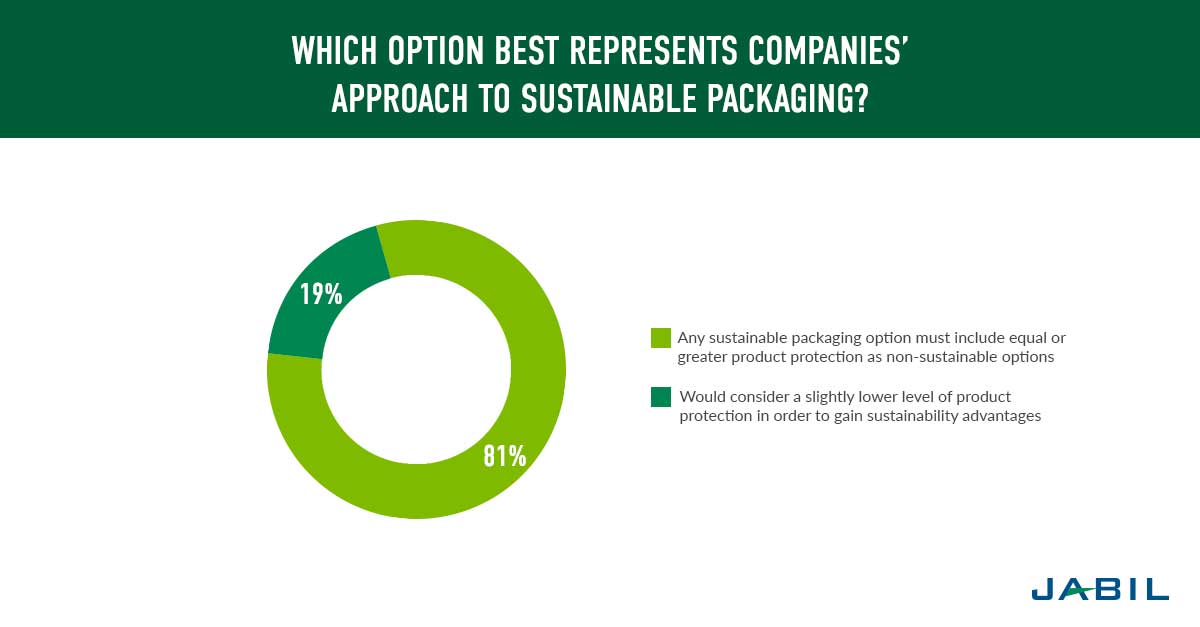

To put it bluntly, plastic is really good at what it was designed to do: guard products from pressure, light, humidity and bacteria. Understandably, according to our survey results, the majority of packaging decision-makers are not willing to sacrifice any degree of protection; sustainable packaging solutions must provide at least equal protection as their current offerings. Additionally, plastic is light-weight, sterile and cost-effective, and, unfortunately, no solutions produced thus far have succeeded in achieving all of those accolades.

Furthermore, although lingering plastic is dangerous for the environment, it does emit less carbon than alternative packaging materials. Glass, for example, is heavy and delicate, so it needs to be well-packed to avoid cracking or shattering, contributing to the rampant overpacking problem, which I will discuss in more detail later. Any kind of breakage on a filling line is a tremendous downtime event; it requires collecting the pieces, throwing away everything in the batch and cleaning the entire line. Additionally, because glass is heavier, it causes more carbon emission in transportation.

These factors make plastic extremely difficult to replace in packaging design. But several organizations and companies are experimenting with innovative solutions. For example, the graduate students from the packaging and industrial-design department of Pratt Institute were recently tasked with designing new forms of food packaging with sustainable materials. Some inventive students baked 3D-printed straws out of sugar and agar (a gelatinous substance taken from seaweed), while others formed bowls out of mycelium, the thread-like roots of mushrooms, envisioning consumers simply tossing their used packages into a compost bin.

Opportunities and Challenges with Biodegradable, Compostable and Bioplastic Packaging

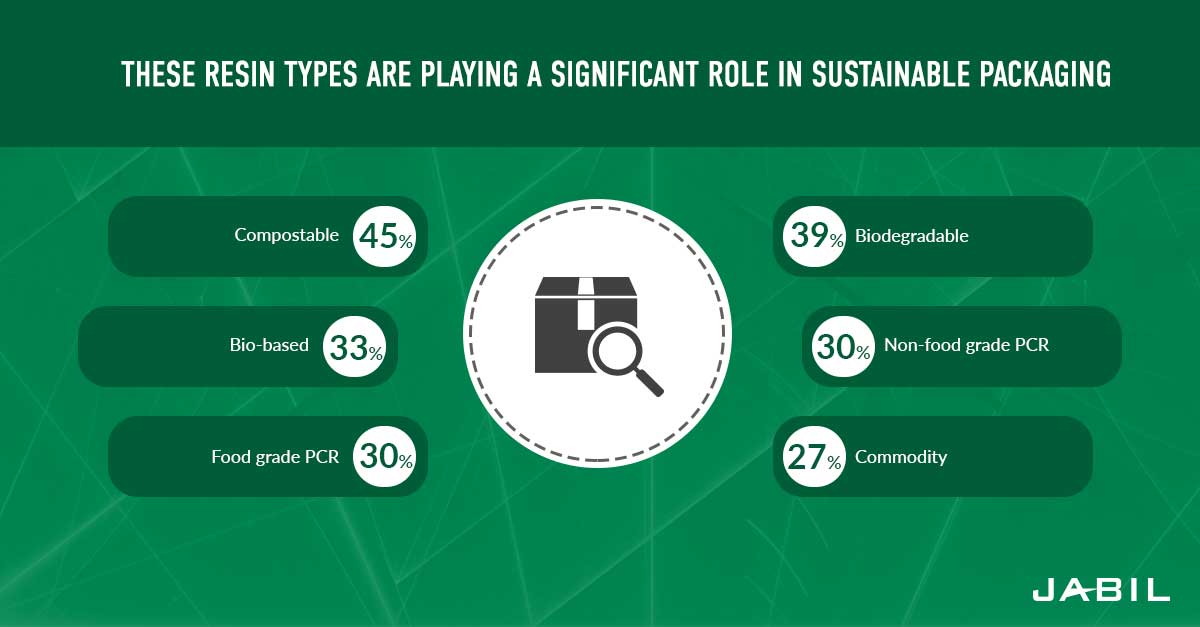

Right now, many companies are investing their time and resources into developing biodegradable, compostable or bio-based packages.

The term “bio-based plastics” refers broadly to substances derived from plant-based material, such as starch and cellulose, whether wholly or in part. Two of the most common feedstocks for bio-based packages are corn and sugarcane, but inventors have also engineered ways to leverage banana peels, mango skins, and potato cuttings. Although not all bioplastics are biodegradable, most of them are, and they, therefore, face the same advantages and challenges as biodegradable or compostable materials.

There are many environmental advantages to investing in biodegradable or compostable materials. One of the most obvious advantages is that because they are designed to decompose – as opposed to fossil-fuel plastic, which may last 450 years or longer– they can reduce waste. Furthermore, because they are created from natural sources, they can conserve petroleum supplies. According to Sciencing, they also offer tremendous energy savings; for example, PLA (a corn-based plastic polymer) uses 65 percent less energy than a comparable polymer from raw petroleum. It also generates 68 percent fewer greenhouse gases during the manufacturing process.

Major companies, including Nokia, P&G, Samsung, Gillette, and Schick, have partnered with Be Green Packaging to deliver a molded fiber packaging solution that is biodegradable and compostable. Be Green leverages a blend of renewable, natural fibers to produce packaging solutions and foodservice containers and strives to ensure that the products their suppliers provide have been grown and harvested in a sustainable manner.

Despite the advantages, a major obstacle to the efficiency of this packaging design approach is that people are not well-educated on the exact definition and implications of the terms “biodegradable.” Contrary to popular perception, biodegradable materials do not simply dissolve into organic matter. Being biodegradable means that bacteria will break down the material if the conditions are suitable.

Even environmentally conscious consumers can fall into the trap of thinking that just because a package is labeled “biodegradable” it absolves them from disposal responsibility, thereby rendering these solutions equally ineffective. Often, they think that just because a package is labeled “biodegradable” or “compostable,” they can just drop it anywhere and allow it to naturally dissolve into organic matter.

But the reality is that if a package – even one made of organic materials – is not disposed of through the correct processes to ensure that it is placed in the conditions that allow it to decompose, it can have a detrimental effect on the environment. For example, biodegradable packages will rarely dissolve in marine water, making them as harmful as plastics.

In fact, according to a report released by the United Nations back in 2015, widespread adoption of biodegradable materials will not significantly decrease the volume of plastics finding their way into the ocean or the physical and chemical risks that plastics pose to the environment.

Therefore, while designing packages with biodegradable, compostable or bio-based materials will be a step toward sustainability, they still need the proper infrastructure and consumer education and buy-in to be successful.

Design Smaller and Lighter

One of the biggest challenges, particularly for the increasingly popular e-commerce industry, is developing compact packaging. Retailers are working to conserve material by making the walls of their packaging thinner and lightening the weight of their packaging. In addition to ecological benefits, this lowers material consumption and shipping cost and inefficiency, making it more appealing to consumers and leading to greater profitability for businesses.

However, with more consumers shopping through e-commerce and online retailers concerned about product safety, many online retailers are overusing materials. This results in excess boxes and product padding that is thrown out and wasted.

One company helping lead the charge in reducing excessive packing materials is Amazon. More than a decade ago, it launched its certified frustration-free packaging, an initiative that ships products in easy-to-open boxes that cut down on excess materials and use 100 percent recyclable materials. For example, through participation in frustration-free packaging, Philips was able to reduce the number of packaging components for their Norelco One Blade by 31 percent, packaging volume by 80 percent and the volume of empty space by 82 percent.

In addition to material reduction, companies should also consider ways to implement volume reduction. Not only does this decrease overpacking, but it also allows more packages to be organized in a space-efficient manner, thereby making transportation easier, more efficient and less harmful to the environment.

Subscribe to the Jabil Blog

Sign up for weekly updates on the latest trends, research and insight in tech, IoT and the supply chain.

Stick to a Single Polymer Group

The current recycling infrastructure needs an overhaul, but in the meantime, manufacturers can design packages to optimize recyclability, working within the boundaries of the current infrastructure. Unfortunately, although there are exceptions – for example, PET bottles and PP closures will separate in float sink processing, and therefore, both are captured successfully in PET recycling – the current recycling infrastructure is not always designed to process packages made with more than one material. Nevertheless, multi-material flexible packaging, especially food pouches, often made from melded layers of aluminum and plastic, is anticipated to be one of the fastest-growing packaging formats over the next few years. Already, Americans alone are estimated to go through 92 billion of these pouches a year.

Traditionally, this inability to separate materials poses a challenge for many different types of packages. For instance, pasta boxes can be problematic; many have transparent “windows” on the front that allow shoppers to see the shape and size of the raw pasta inside. However, because these “windows” are not made of the same cardboard as the box, it makes the package difficult to recycle.

Packaging stakeholders can start to make a difference by redesigning their products to fit within a single polymer group.

Make Packaging Reusable

Given the weaknesses within the recycling infrastructure, it may be a more effective option to design packaging that isn’t meant to be disposed of. Some of the biggest brands in the world are wheeling out reusable packaging to move away from the single-use plastics that are increasingly under regulatory scrutiny.

Many industry-leading companies are partnering with global recycling organization TerraCycle in an initiative called “Project Loop” to introduce reusable packaging options to their customers and make the circular economy more commercially viable.

For example, Unilever’s Axe and Dove deodorants will come in refillable containers that are predicted to last eight years or at least 100 usage cycles. “Made from stainless steel, the design is minimal, compact and sustainable, offering a new consumer experience without any unnecessary materials,” the company stated in a press release.

Likewise, Nestlé is working with TerraCycle, governments, NGOs, suppliers, waster managers, retailers and more to completely eliminate its single-use plastics, such as films, ice cream cone wrappers and paper cups, and make all of their packaging recyclable or reusable by 2025. They are testing refillable containers for their Häagen-Dazs ice creams as well as a subscription home delivery service for foods and household goods that uses reusable packaging.

"Loop provides a much-needed innovation platform, challenging companies to take a fresh look at our value chains and integrate reusable product packaging as part of our efforts to waste-reduction,” said Laurent Freixe, Nestlé CEO for Zone Americas.

Although it will take innovation and commitment, it doesn’t require a mad genius to produce sustainable packaging solutions. Personal accountability and actions are what will lead to the reward of more sustainable solutions and a healthier planet. Everyone has a role to play in ushering in the circular economy; corporations, governments, and individuals must be willing to accept to take responsibility for proper disposal and waste management and work together to create and implement end-to-end solutions. But ensuring optimized usage and successful end-of-life requires a vision from the very beginning of the process. It starts with sustainable packaging design.

Download the Sustainable Packaging Trends Survey Report

Insights from over 200 packaging decision-makers at global enterprises on their sustainable packaging goals, initiatives and challenges.