Among Sustainable Options, Paper Packaging Delivers

Growing awareness of plastic pollution has influenced public opinion and led to significant changes inside most consumer packaged goods (CPG) brands. Notably, they have centered around two main ideas: Use less plastic and incorporate as much recycled material as possible in options like paper packaging.

A 2021 progress report from over 500 signatories of the Ellen MacArthur Foundation's New Plastics Economy Global Commitment — whose primary focus is reducing single-use plastics and prioritizing reuse, recycling and compostable materials — found that brands' use of virgin plastic is set to drop 20% by 2025. But what steps are they taking to eliminate plastic from their packaging portfolios?

Jabil's 2022 Sustainable Packaging Survey indicated that many are interested in swapping paper for plastic. More than two-thirds (68%) of companies surveyed are working to implement paper-based packaging, and nearly half (49%) said their highest sustainable packaging priority is implementing paper-based packaging.

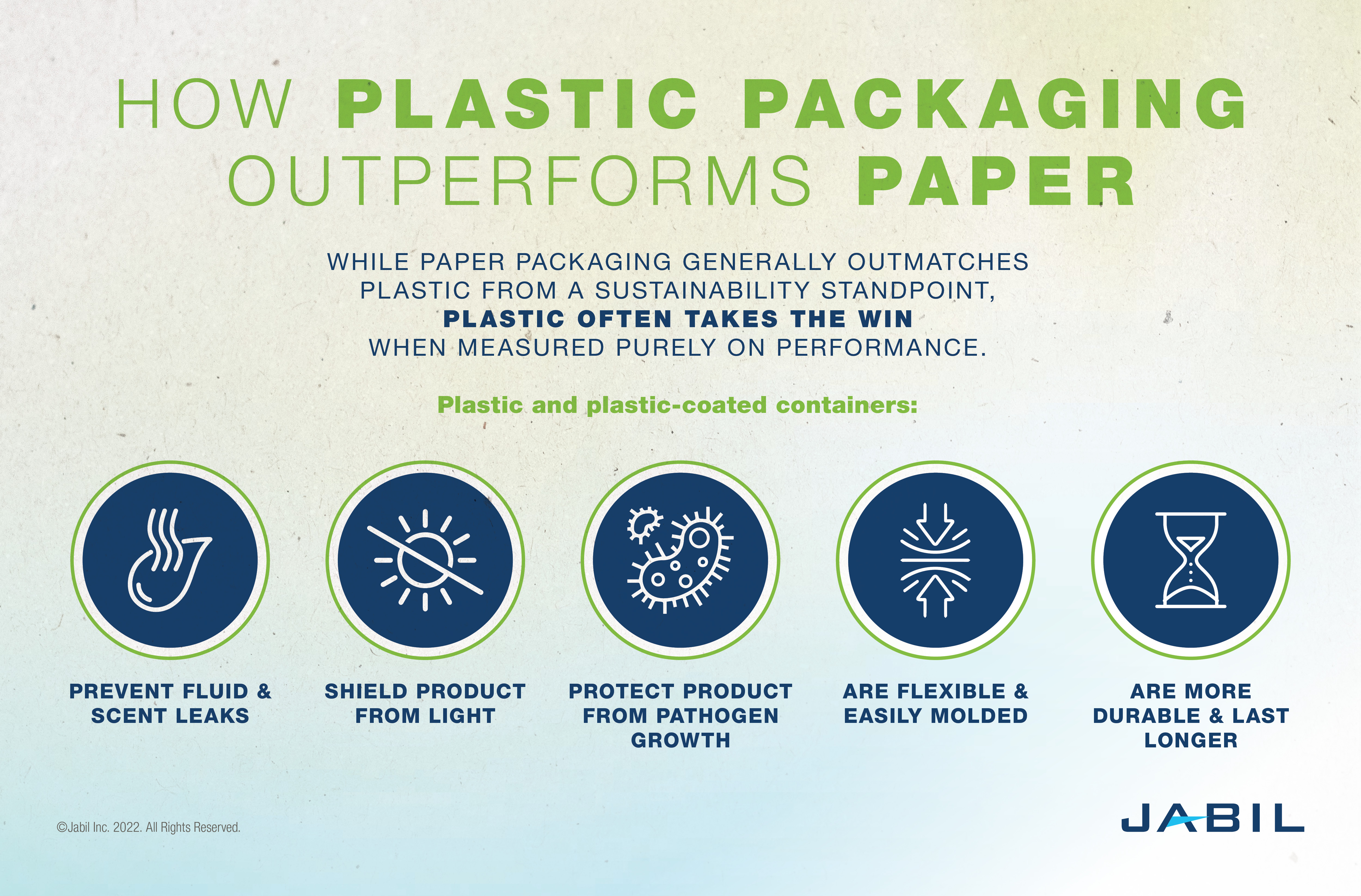

However, making the switch from plastic to paper is a decision that presents both challenges and opportunities. Plastic is the preferred material in the packaging space for a reason. It provides a wide array of barrier properties that protect the product. It's lightweight, and its production and transport have a relatively low carbon footprint compared to heavier materials like glass and metal. It comes in a vast array of colors and can take on countless forms. However, it can also be challenging to recycle, requires the use of fossil fuels to produce and takes hundreds of years to decompose in a landfill, which creates microplastics in the environment.

Paper, on the other hand, is beautiful in its simplicity. It is widely recycled and is renewable, meaning that trees can be regrown and harvested like other plant-based crops. But paper has its limitations in commercial packaging uses, as it lacks barrier protection for common products such as liquids, creams and some oxygen-sensitive goods.

.jpg)

In solving this paper paradox, there are some tough challenges CPGs and their packaging suppliers must overcome. How can we improve the performance of paper packaging without negating its natural sustainability benefits? Let's first examine the environmental advantages paper offers.

The Sustainability Benefits of Paper Packaging

Paper is not a complicated material. It is made from natural plant materials, and its production has a relatively low carbon footprint compared to the production of other packaging materials — particularly if the packaging is made from recycled paper material and no additional deforestation is required for its creation. And as uncoated paper is simple to construct, it is also simple to deconstruct, making it an ideal material for recycling and reuse.

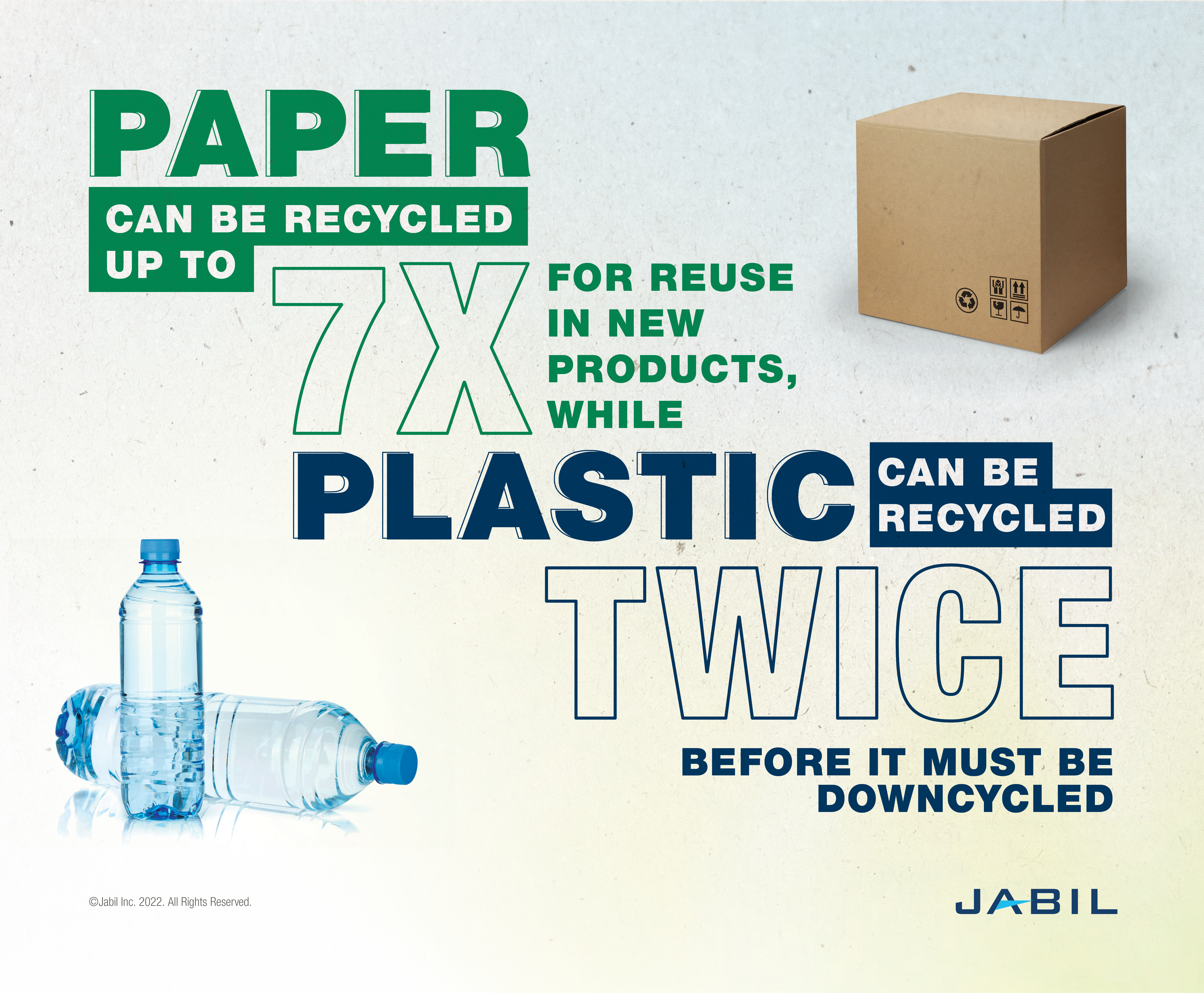

While steel is the most recycled material globally, the EPA's most recent data shows that paper and paperboard are the most-recycled materials in the United States. According to the American Forest & Paper Association (AF&PA), the 2020 paper recycling rate was about 66%. For comparison, the OECD found in their 2022 Global Plastics Outlook that only 9% of plastic is recycled worldwide; that rate is even lower in the United States, where only 4% of plastic is recycled annually. With continued recycling, paper and cardboard can live a long lifetime. The EPA estimates paper can be recycled up to seven times for reuse; even then, it can be used to make paper paste for newsprint, egg cartons or other lower-quality paper products. Compare that to plastic, which, if recycled mechanically, can only be reused once or twice before it is then downcycled for use in goods like clothing and shoes.

.jpg)

The AF&PA has found that most recycled paper is used to manufacture boxes — either containerboard, the material used to make corrugated boxes (41.5%) or boxboard, used for small containers like cardboard takeout boxes or gift boxes (12.6%). Tissues, paper towels and newspapers are other common products made from recycled paper.

.jpg)

For consumers, seeing paper packaging where they expect plastic is a visual cue that a CPG is serious about making a commitment to sustainability. Material substitutions, such as using paper instead of plastic, are often more obvious to shoppers walking down a crowded store aisle than a plastic container that has less material. It is often harder for consumers to understand the environmental impact of that decision. As an example, consumers paid little attention to the industry-wide move to cut the amount of plastic in single-use water bottles in the mid-2000s except to note that the new containers were more fragile than their heftier counterparts. However, a bottle made from paper helps consumers immediately make the connection to sustainability.

The fact that paper as a material is so intuitive is what seems to connect consumers with the package and makes paper's end-of-life story a seemingly positive one. Unfortunately, when it comes to packaging, paper's simplicity means that its performance does not always line up with commercial needs.

Overcoming Paper Packaging's Limitations

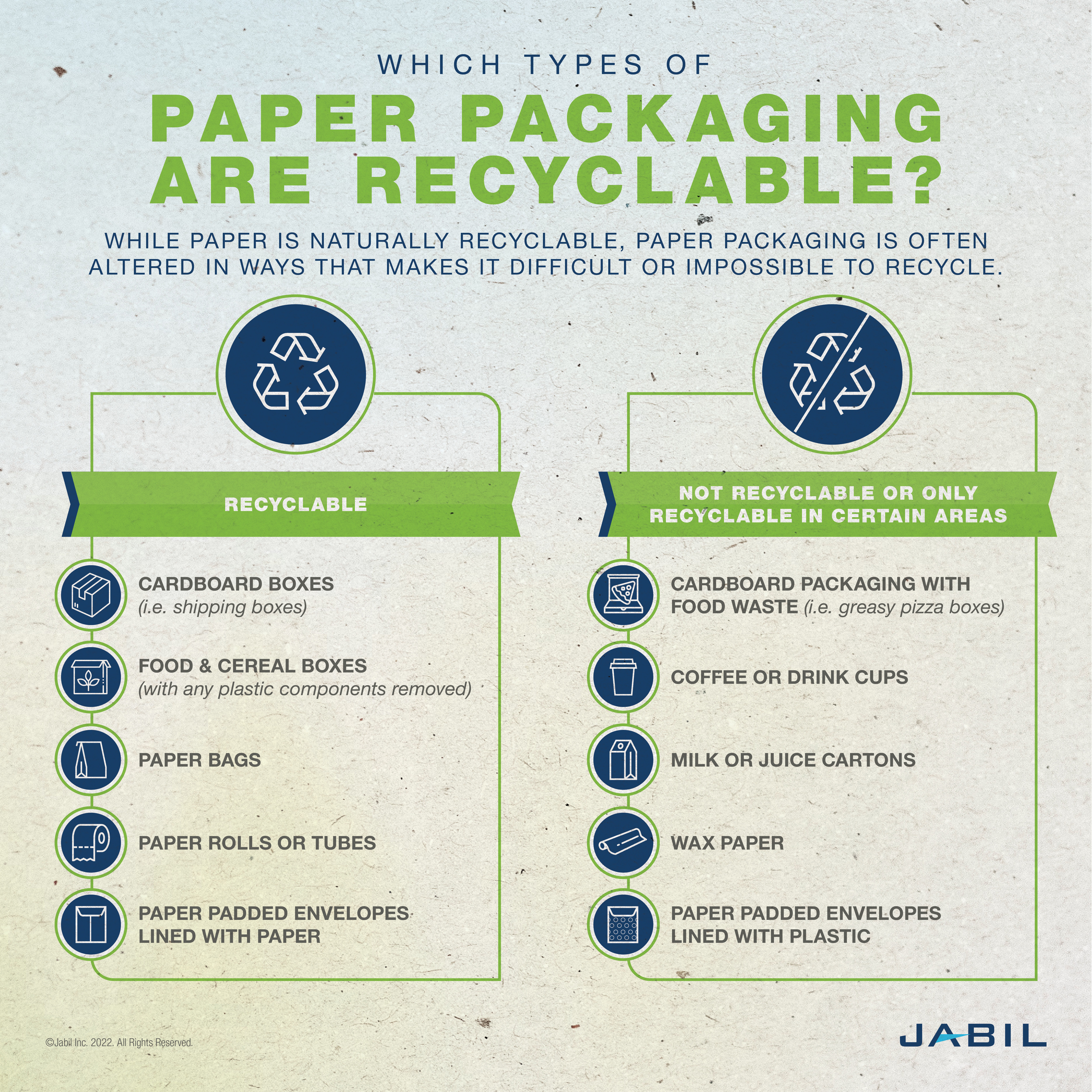

To put it frankly, paper on its own is quite limited in its ability to function as packaging. Without the addition of coatings such as wax, lamination or other plastic materials, it cannot hold liquids, is fairly fragile and can be difficult to mold in shapes other than variations of squares and rectangles.

Cardboard boxes aside, many forms of paper packaging require some amount of plastic to make it functional, protecting the product from liquid or fragrance leaking, exposure to light, and pathogen growth. That plastic then makes at least part of the container not recyclable.

.jpg)

Take a paper-based carton used to hold milk or juice. It's protective, cost-effective and a familiar format to consumers. But it is coated with laminate on all sides and includes a plastic closure that makes the package incredibly difficult to recycle. Not every paper facility can process coated paper. Even if a particular facility can process the container, large amounts of water and energy are needed to separate the paper fibers from the plastic laminate, yielding a relatively small amount of recyclable paper in addition to the plastic that must be discarded.

As brands reevaluate and redesign their sustainable packaging portfolio, the prevailing goal is plastic reduction. At this point, it's unclear if or when it will be possible to completely eliminate all plastic from paper packaged products that need high levels of barrier protection, like personal and home care liquids, refrigerated or frozen foods, and medicines. According to Jabil's 2022 Sustainable Packaging Trends survey, however, nearly one-third of respondents (32%) said they would consider a slightly lower level of product protection in order to gain sustainability advantages — creating an opportunity for CPGs to explore options within the paper space. For example, does a body wash that is, on average, consumed within 16 months after its production truly require a bottle made from thick plastic that provides 24 months of protection? Or could it be packaged in a lighter, thinner plastic bottle (or even a hybrid paper bottle) that provides a shelf life more aligned with consumer behavior?

Improving Paper Packaging's Performance

In a world where paper packaging still requires some amount of plastic to be effective, those of us innovating in the packaging space must ask ourselves: How do we maximize the benefits of paper without sacrificing other areas of sustainability? Here are a few considerations for CPGs exploring paper packaging:

1. Prioritize the Consumer Recycling Experience

Paper's sustainability is largely due to its recyclability. Wherever possible, consider designing paper packaging in such a way that the plastic and paper components can be easily separated and disposed of (either recycled, composted or thrown away) according to the specific needs of the material. To maintain recyclability, minimize the use of coatings, adhesives or other material additions to the paper that will render it not recyclable.

For example, Ecologic's eco.bottle uses a strong, uncoated paper shell around a thin plastic liner, which prevents the liquid inside from leaking. The two layers are mechanically connected using interlocking paper tabs rather than glue. When a consumer is finished with the product, they can simply separate the paper and plastic layers at the seam and recycle each component in their respective recycling streams.

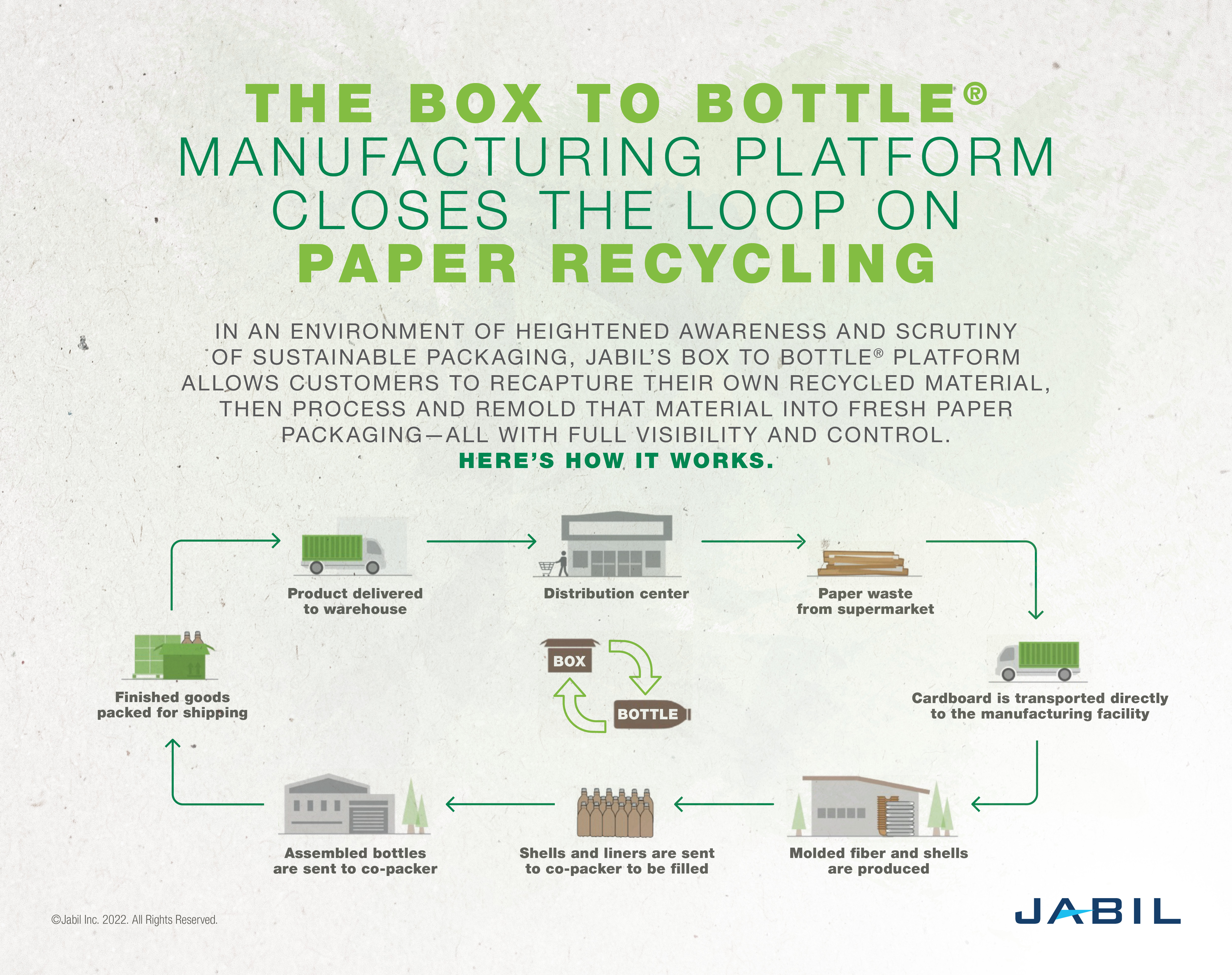

2. Close the Loop

Encouraging consumers to recycle their paper packaging after consumption has obvious sustainability benefits, but it can have business benefits as well. CPGs should not only consider using exclusively post-consumer recycled paper and plastic in their packaging, but also taking ownership of their supply chain by developing a proprietary source of recycled material. At Jabil, we work with our customers to help them capture, process and remold recycled paper waste for use in their products. We do the same for Ecologic, and each of our containers uses 100% recycled paper. By controlling the recycling stream, brands gain unprecedented visibility into the circularity of their production process.

Similar streams can be created for recycled plastic components that are integrated with paper packaging. Unlike coated paper, separable paper shells and plastic linings can be both recycled and remade using post-consumer material.

.jpg)

3. A Powerful Combination Creates New Shapes

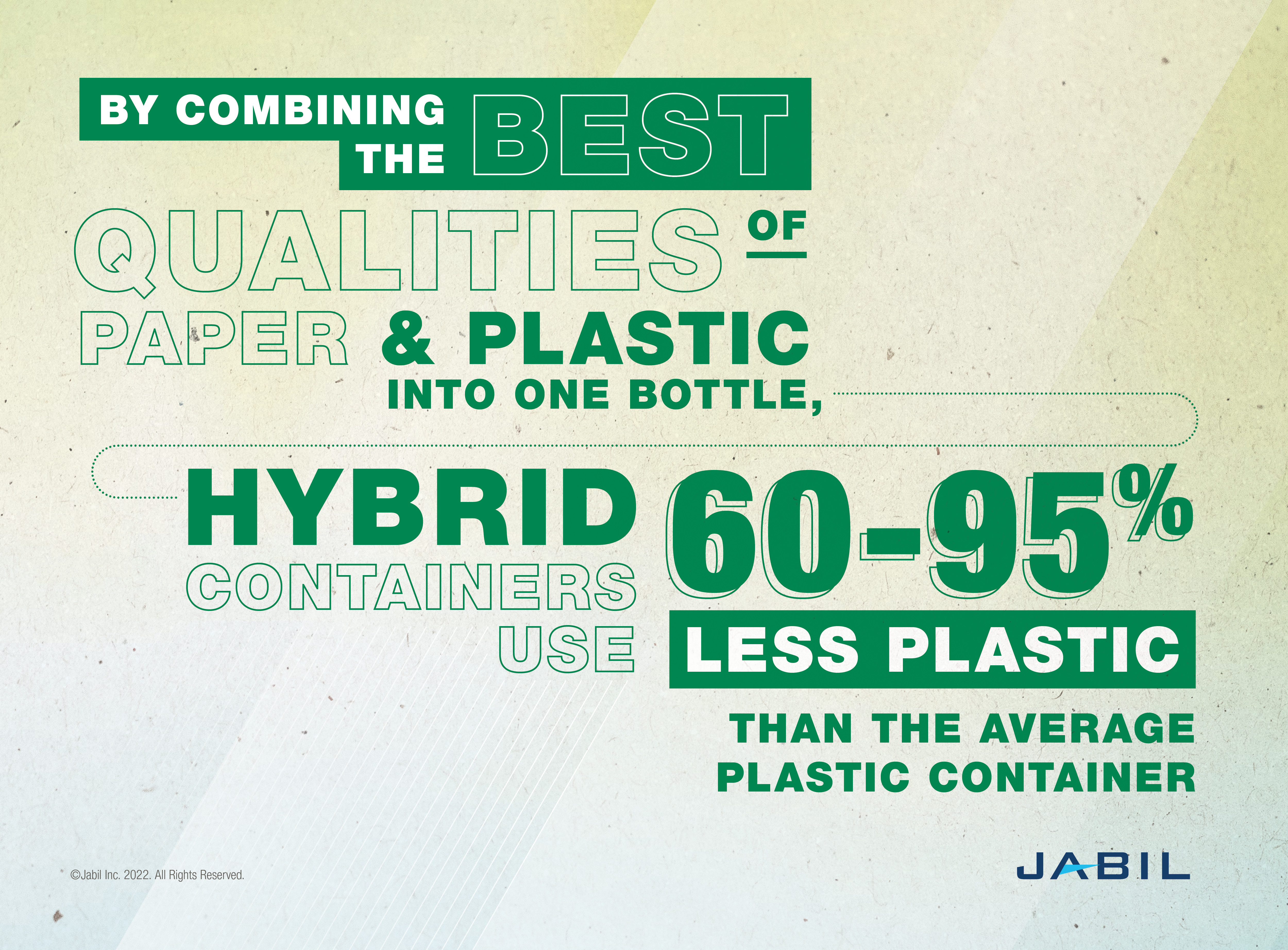

Paper packaging, including coated paper packaging, has traditionally only been folded a select number of mostly rectangular ways — none of which are quite as functional as cylindrical bottles or tubs. Now, with control over their own paper supply and the integration of lightweight plastic liners, brands can mold, rather than fold, paper into a wide range of formats that solve for nearly every packaging use case. Personal care pump bottles, cosmetics jars, home care spray bottles, food tubs and more are all possibilities with the thoughtful combination of paper and plastic. By leveraging the best qualities of each material, Ecologic's hybrid containers use 60% to 95% less plastic than the average plastic container of the same size.

.jpg)

Consumer packaged goods brands have set lofty plastic reduction goals for the next five to 10 years. To the average consumer, a 20% reduction by a single company may sound like its impact would be negligible. But expand that out to the 500 signatories of the New Plastics Economy Global Commitment, and that means 40 million barrels of oil that would have previously become plastic stay in the ground.

The good news is that brands have made significant commitments to minimizing the impact of plastics and elevating the roles CPGs can play; in Jabil's survey, we found that reducing their contribution to ocean plastics is a sustainable packaging goal of 59% of respondents, while 53% want to cut their single-use plastics overall. Still, when considering a switch to a material like paper, CPGs must remember that all production has environmental impact and some degree of waste associated with it. Cutting down trees to produce a plastic-free but ineffective product is likely not worth the stress on the environment.

There is another way. By making practical decisions to leverage the best qualities of paper, using recycled materials and — perhaps most importantly — educating consumers on the power of the circular economy, brands can take the future of packaging into their own hands.

Download the Sustainable Packaging Trends Survey Report

Insights from over 180 packaging decision-makers at global enterprises on their sustainable packaging goals, initiatives and challenges.

.2023-01-11-18-03-30.jpg)